commercial lighting applications for warehouses

You want to use commercial lighting, which is to illuminate a lot of space.

Not only do you need to illuminate the interior of the warehouse space, but in order to ensure safety, safe lighting on the outside may also be necessary.

When choosing commercial lighting for your space, make sure you have an action plan about what you want to do.

You need proper lighting in order to manage the warehouse.

You would like to be able to see your inventory clearly, and if you have a night staff or cargo coming in late at night, it is critical to have plenty of light.

There are many different commercial lighting options.

You have high bay and low bay lights, floodlights and wall packs.

Some of them are different light bulbs that give off different degrees of glare.

For example, if you carry a product of different colors and it is important to be able to see the real color, if you are looking for more products, you need to use a working horse with a metal halogen lamp, and then a tall horse.

The pressure sodium bulb may be the way to go.

High Bay lighting is designed for areas with over 20 feet ceilings.

This lighting is very effective in large warehouses or manufacturing facilities.

Once you decide you need a high bay lighting device, the next step is to select the right bulb for the type of warehouse you are running.

There are several types of bulbs for this type of fixture, such as metal halogen lamps, high

Pressure Sodium, mercury vapor and fluorescent bulbs.

Choosing the right light bulb depends largely on your needs.

There are usually two sizes for high bay lighting, 16 or 22 \".

This type of fixture is designed to distribute the light evenly on a large surface, thereby increasing productivity and safety in the area.

Low Bay lighting is designed for commercial environments such as warehouses or manufacturing plants.

Low Bay fixtures are designed for facilities with lower ceiling heights.

This fixture is designed to illuminate larger areas with lower ceilings, enough for workers to produce and ensure safety.

Low Bay lighting equipment can only be used in less than 20 feet of the space of the equipment from the floor.

For this type of fixture, there are a few bulbs to choose from, just like the one in Gaowan.

High-intensity discharge bulbs are usually used in these devices.

Floodlights are usually a good idea to illuminate the outside of the warehouse.

For safety and safety reasons, areas such as parking lots need lighting, which is the perfect choice for floodlighting.

Combine the floodlights with the light poles and you can illuminate the exterior of the warehouse.

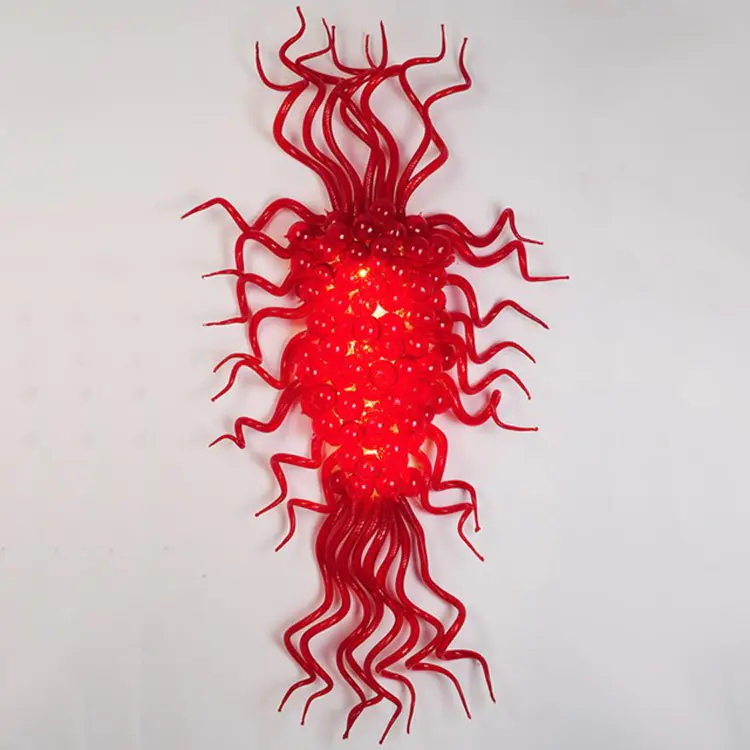

Wall packs are a great way to protect and illuminate the outside area of the warehouse, especially the side and back of the building.

Wall packs do a great job of illuminating the exterior of the warehouse, but for beauty, it is better to use floods to illuminate the front of the warehouse and use Wall packs on the side and back.

The most commonly used Wall package is 175-

Watt metal halides or 400 watt high-

Pressure Sodium Wall bag.

However, if you are in a state where dark sky regulations occur, you will need to find the zero site Line Wall package in order to comply with the regulations.